Why Silicone Is a Preferred Gasket Material

Silicone has earned its reputation as one of the most adaptable elastomers due to its unique combination of physical and chemical properties. It offers excellent resistance to extreme temperatures, retaining flexibility in both freezing and high-heat conditions. This makes it suitable for applications that involve continuous exposure to ovens, engines, or refrigeration units. Additionally, silicone demonstrates impressive resistance to ultraviolet light, ozone, weathering, and many chemicals, ensuring long service life even in outdoor or industrial environments.

The material also possesses low toxicity and biocompatibility, which is why it is frequently used in medical devices and food-grade sealing applications. Its non-reactive nature ensures safety when in contact with sensitive environments such as pharmaceuticals, consumables, or laboratory equipment. By leveraging these qualities, manufacturers can create custom silicone gaskets that meet strict regulatory and functional requirements.

The Role of Customization in Gasket Performance

While silicone itself provides a strong foundation, the customization process ensures that gaskets meet the exact demands of a particular application. Standard gaskets may not account for unique shapes, tolerances, or environmental challenges. In contrast, customized designs allow for precise dimensions, material durometers, and specialized coatings that improve performance.

For example, medical equipment may require silicone gaskets that are sterilizable and free from impurities, while aerospace systems often demand lightweight yet durable seals capable of withstanding rapid temperature fluctuations. In the electronics sector, customized gaskets provide dust and moisture protection for delicate components without compromising conductivity or insulation. This flexibility highlights the importance of tailoring each gasket to its intended use rather than relying on generic, mass-produced alternatives.

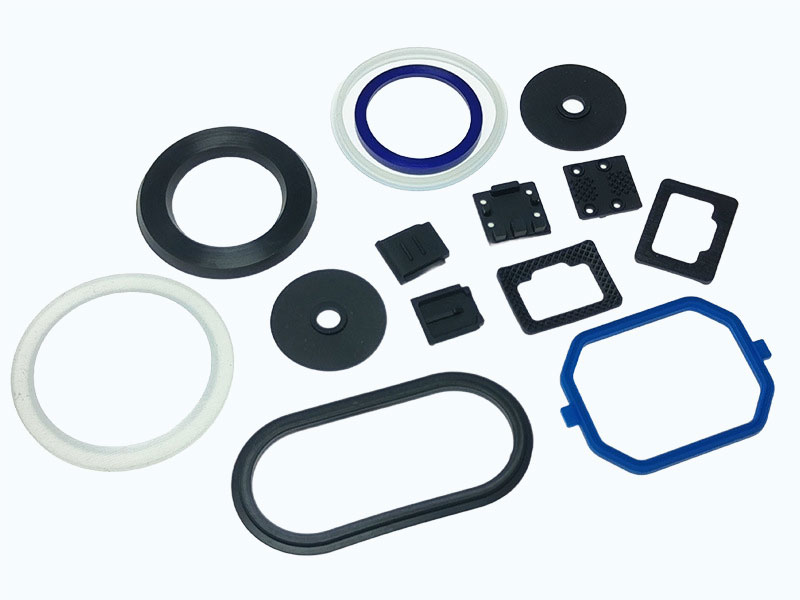

Applications of Custom Silicone Gaskets Across Industries

The wide adoption of silicone gaskets is evident in their diverse applications. In the automotive field, they are used for sealing engines, transmissions, and HVAC systems, where exposure to heat, oils, and vibration requires high reliability. Aerospace relies on silicone’s stability in high-altitude and fluctuating temperature conditions, ensuring safety and efficiency in flight-critical systems.

In healthcare, silicone gaskets are integral to devices such as ventilators, pumps, and diagnostic machines, where sterility and biocompatibility are essential. The food and beverage sector uses food-grade silicone seals in processing equipment to maintain hygiene and prevent contamination. Even consumer electronics integrate silicone gaskets to provide waterproofing, dust resistance, and thermal stability, protecting sensitive devices like smartphones, tablets, and wearable technology.

The Manufacturing Process Behind Custom Silicone Gaskets

The production of custom silicone gaskets involves several critical stages. It typically begins with a consultation and design phase, where engineers evaluate application needs and determine the most suitable silicone formulation. Computer-aided design tools are often employed to ensure precision in dimensions and performance characteristics.

Once the design is finalized, silicone can be shaped into gaskets through methods such as die-cutting, waterjet cutting, or molding. Compression molding and injection molding are particularly popular for producing high volumes with consistent quality. Depending on the application, manufacturers may also apply adhesives, coatings, or treatments to enhance durability, reduce friction, or improve chemical resistance.

Stringent testing follows, ensuring that each gasket meets required standards. Properties such as compression set, tensile strength, elongation, and thermal resistance are measured to guarantee consistent performance. Industries like aerospace and healthcare impose especially strict quality control measures, making reliability a top priority.

Advantages of Choosing Custom Silicone Gaskets

custom silicone gaskets offer several benefits that extend beyond those of standard sealing solutions. Their ability to maintain elasticity and sealing capability across wide temperature ranges ensures fewer failures and reduced maintenance costs. Customization allows for an exact fit, which not only improves performance but also reduces energy loss, leakage, and system inefficiencies.

Another significant advantage lies in compliance with regulatory requirements. Food-grade and medical-grade silicone gaskets are manufactured to meet FDA, USP, or ISO standards, ensuring safety in critical applications. Furthermore, silicone’s long lifespan minimizes replacement needs, offering cost efficiency over time. The adaptability of silicone formulations, from soft and flexible grades to more durable high-strength versions, provides industries with unmatched design freedom.

Selecting a Reliable Manufacturer

The effectiveness of a custom silicone gasket depends heavily on the expertise of the manufacturer. An experienced supplier brings technical knowledge, advanced equipment, and a thorough understanding of industry regulations. Working with a manufacturer that prioritizes collaboration during the design stage ensures that the final gasket aligns with both functional and compliance requirements. Prototyping, testing, and transparent communication throughout the production cycle are also essential to achieving optimal results.

Future Trends in Silicone Gasket Manufacturing

Innovation in material science and production methods continues to shape the future of silicone gaskets. Advanced formulations are being developed to improve resistance to extreme chemicals, fire, and abrasion, broadening their applications. The rise of rapid prototyping and additive manufacturing is accelerating development timelines, allowing companies to test and refine gasket designs more efficiently.

Sustainability is also becoming a central focus, with growing interest in recyclable or eco-friendly silicone alternatives. As industries evolve and place greater emphasis on environmental responsibility, manufacturers are expected to adopt greener practices without compromising performance.

Conclusion

Custom silicone gaskets stand at the intersection of versatility, reliability, and innovation. Their unique material properties, combined with precise customization, make them a vital component across industries that require dependable sealing solutions. From protecting sensitive electronics to ensuring the safety of medical devices and the efficiency of heavy machinery, these gaskets demonstrate the power of tailored engineering.